Discover How Membrane Switches Function and Their Duty in Modern Electronic Devices

Membrane Switches represent a sophisticated assimilation of modern technology and style within the realm of modern electronics, functioning as essential user interfaces in various devices. Comprised of numerous layers, these buttons make use of pressure-sensitive devices to promote user communication. Their applications span numerous markets, from customer electronic devices to clinical devices, highlighting their flexibility and significance. Understanding the details of Membrane button functionality and their broader ramifications in enhancing customer experience welcomes additional expedition into their layout, advantages, and the innovative advancements forming their future in innovation.

What Are Membrane Buttons?

Membrane buttons are identified by their sturdiness and resistance to ecological factors, such as dust, dampness, and extreme temperature levels. They can be tailored with numerous graphics, shades, and responsive responses alternatives, improving individual experience while preserving aesthetic charm - membrane switches. In addition, the unification of printed circuits enables for smooth assimilation right into tools, improving general capability.

The convenience of Membrane buttons appears in their capability to sustain both basic and intricate control functions. They can incorporate functions such as LED indications and touch-sensitive innovation, providing to details customer needs. As technology remains to evolve, Membrane Switches stay essential for making it possible for reliable and intuitive user interfaces, thereby playing a pivotal duty in the development of modern digital tools.

Parts of Membrane Buttons

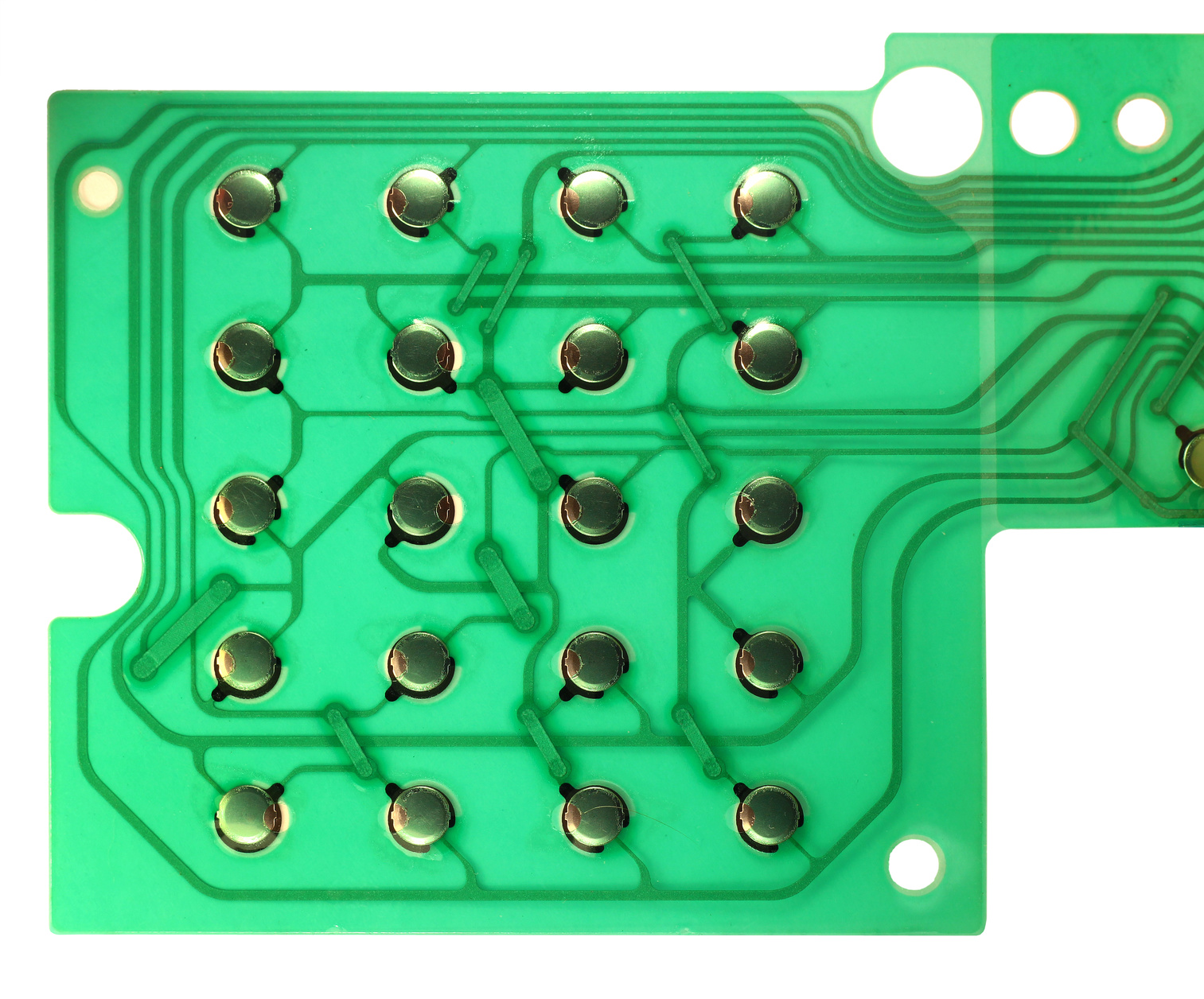

Membrane switches are made up of several vital elements that function together to produce a trustworthy and functional interface. The primary components include the graphic overlay, adhesive layer, spacer layer, and conductive traces.

The graphic overlay acts as the customer interface, normally published on a versatile substrate such as polyester or polycarbonate. This layer not only offers aesthetic charm but also includes responsive comments, aesthetic hints, and safety functions. Under the visuals overlay lies the sticky layer, which protects the button to the tool and makes certain longevity against environmental stress and anxieties.

The spacer layer is crucial for maintaining the required space between the visuals overlay and the circuit layer. This void enables the activation of the switch when stress is applied. The conductive traces, normally made from silver or carbon, form the electric paths that complete the circuit when the switch is involved.

Additionally, a backing layer might be consisted of for structural support and insulation. These parts team up seamlessly, ensuring that Membrane switches are both durable and user-friendly, making them essential in different modern digital applications.

Exactly How Membrane Switches Job

Exactly how do Membrane Switches feature successfully within digital tools? Membrane Switches operate the principles of pressure-sensitive technology, utilizing a layered construction that consists of visuals overlays, sticky layers, and conductive components. When a customer uses stress to the switch, the leading layer warps, enabling the conductive components under to make contact and finish an electrical circuit. This action causes the preferred function within the tool.

The style of Membrane buttons is important for their reliable procedure (membrane switches). The layers are meticulously engineered to offer responsive feedback, resilience, and resistance to ecological factors such as moisture browse around these guys and dirt. The addition of domes-- tiny, raised locations within the button-- enhances responsive action, offering users with an obvious click sensation upon activation

Moreover, Membrane buttons can be tailored in terms of dimension, form, and graphics, making them ideal for numerous applications. They are typically made use of in control panels, clinical tools, and customer electronics as a result of their smooth layout and integrity. Generally, the reliable performance of Membrane buttons is pivotal in improving user interaction and making certain smooth procedure in modern digital devices.

Applications in Modern Tools

Using their distinct style and capability, Membrane switches have actually come to be integral elements in a broad array of contemporary digital tools. These flexible interfaces are used in consumer electronic devices, industrial equipment, medical tools, and auto controls, giving smooth customer interaction.

In consumer electronics, Membrane switches are typically found in devices like microwaves, washing devices, and other visit this web-site household tools, where they enable instinctive control with a smooth profile. Their low-profile layout facilitates assimilation into portable redirected here devices, boosting aesthetic allure without compromising functionality.

In commercial applications, Membrane Switches offer as control board for machinery, supplying longevity and resistance to harsh settings. Their capacity to endure moisture and contaminants makes them perfect for usage in production and handling industries.

Medical gadgets likewise gain from Membrane switches, which are created to be very easy to tidy and maintain, making certain hygiene in scientific settings. They are often utilized in analysis tools, individual surveillance systems, and mobile clinical devices, where reliability is critical.

Advantages of Membrane Buttons

Among the vital advantages of Membrane buttons is their convenience, which enables them to be customized for a selection of applications across numerous markets. These buttons can be developed in various sizes and shapes, fitting special product needs while offering seamless integration right into gadgets. Their slim profile enables a streamlined and small style, usually boosting the visual charm of electronic items.

One more considerable advantage is their resilience - membrane switches. Membrane buttons are generally immune to dust, dampness, and chemicals, making them perfect for extreme environments. This strength prolongs their life-span compared to typical mechanical switches, decreasing the need for frequent replacements

Additionally, Membrane Switches offer cost-effectiveness. The manufacturing procedure involves printing modern technologies that minimize production costs, particularly for big runs. This affordability, incorporated with reduced maintenance demands, makes them an appealing option for producers.

Verdict

In final thought, Membrane Switches represent a significant innovation in customer interface innovation within modern electronic devices. As the demand for intuitive and resistant interfaces continues to expand, the role of Membrane buttons in shaping user experience will definitely expand.

Membrane Switches stand for an innovative combination of modern technology and design within the realm of modern-day electronics, serving as crucial user interfaces in numerous gadgets.In the realm of modern electronics, Membrane Switches offer as crucial parts that help with customer interaction with tools. As innovation proceeds to develop, Membrane Switches remain crucial for allowing effective and user-friendly user interfaces, therefore playing an essential role in the development of modern digital devices.

How do Membrane Switches feature properly within digital tools? Overall, the reliable functioning of Membrane buttons is pivotal in enhancing user communication and making sure seamless procedure in modern-day electronic tools.